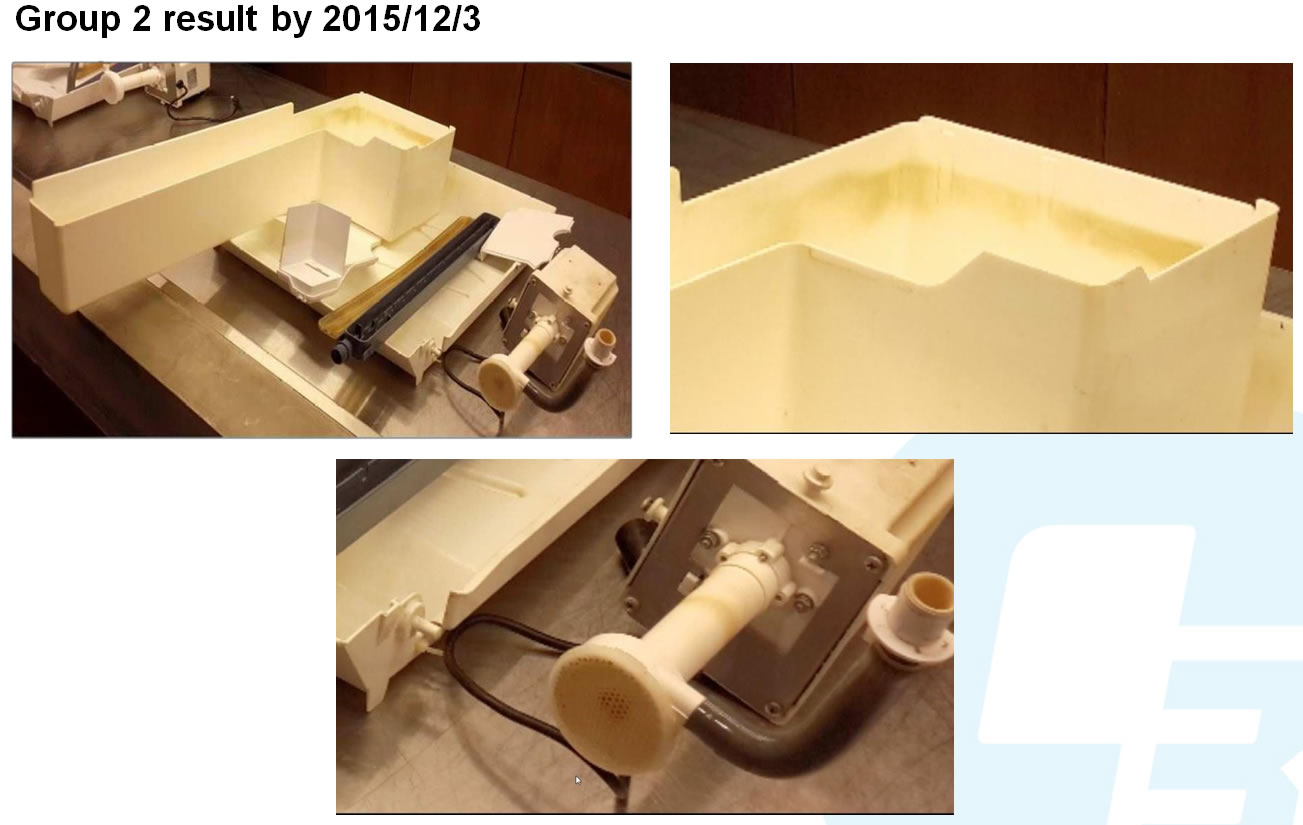

If you open your commercial ice machine and see a pink slime or film on the interior walls, parts or tubing, means that the bacteria levels are at an aggressive level. Ice Machines that are not cleaned regularly and thoroughly can cause the spread of nasty germs like Salmonella, Listeria, E. coli, Shigella, and the Norwalk virus. Water biofilm is highly complex.

If you open your commercial ice machine and see a pink slime or film on the interior walls, parts or tubing, means that the bacteria levels are at an aggressive level. Ice Machines that are not cleaned regularly and thoroughly can cause the spread of nasty germs like Salmonella, Listeria, E. coli, Shigella, and the Norwalk virus. Water biofilm is highly complex.

They’re self-protective and normal sanitizing can’t kill them. That’s why disease producing bacteria can be extremely difficult to get rid of if it’s living in a biofilm.

Pseudomonas Aeruginosa is ubiquitous to the environment too. It’s a free living bacteria that is often found in natural waters. Most mold and fungi won’t grow in or on the surface of a biofilm when it’s submersed in water, but in an ice maker where surfaces are damp and not submersed, mold and other fungi can grow and possibly find a home in a protective biofilm. This organism is typically found in 2% of drinking water samples. It can also survive in distilled or deionized water.

If you have a biofilm in your ice machine containing Pseudomonas, it can be sloughed off into ice production. In individuals with a compromised immune system, it can cause folliculitis and ear infections or keratitis and eye infections.

Ice makers are also susceptible to brown slime that’s caused by natural occurring airborne yeast. Ice is frozen water but just because it’s frozen, doesn’t mean it doesn’t contain harmful bacteria. Bacteria can live in a frozen environment. Potential causes of illness might include an unclean surface, a dirty filter, or cross contamination from poor handling.

Biofilm happens when cells start to stick to each other and to surfaces causing a build up of bacterial slime. It is best to keep you ice machine cleaning schedule up to prevent this dreaded pick slime from developing.

Biofilm happens when cells start to stick to each other and to surfaces causing a build up of bacterial slime. It is best to keep you ice machine cleaning schedule up to prevent this dreaded pick slime from developing.

You can consider adding water filtration and water sanitation device to your ice machine. Water filtration systems can taking out some unwanted particles and chemicals commonly found in tap water including chlorine, fluoride, lead, and even arsenic. A good water carbon filter can protect commercial ice machines from producing foul tasting and smelling ice. Water sanitization refers to a process of cleaning out harmful pathogens commonly found in water, water lines, and ice machine. Running Ozone through the water line which kills pathogens, and helps keep the water and equipment it comes in contact with cleaner and safe longer. The use of ozone is key because it is a natural and safe alternative to the harmful chemicals that are often used to clean out water lines and ice machines. As an added benefit, the trace amounts of ozone help keep airborne pathogens from growing on the surface of the ice until it is used by customer.

Keeping your restaurant’s ice machines clean does more than just prolong the life of your machine. Remember, ice is a food product that you are giving to your customers. Don’t let that pink film go unnoticed. If you have biofilm it must be addressed immediately for the safety of your customers. Keep your ice machines clean and your customers safe!

| Catalogue | Downoad PDF |